- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

Integration of RFID with ERP

Product Details:

X

Integration of RFID with ERP Price And Quantity

- 1 Unit

Product Description

Integrating RFID with ERP systems can supercharge visibility, automation, and traceability across your operations, especially in industrial environments like yours. Here is a structured breakdown tailored to your analytical style:

Why RFID-ERP Integration Matters

- Real-time asset tracking: RFID tags update ERP databases instantly no manual input required.

- Inventory accuracy: Reduces stock discrepancies and enables automated cycle counts.

- Process automation: Triggers ERP workflows (e.g. goods receipt, WIP updates) based on RFID events.

- Compliance & audit readiness: Maintains timestamped logs for traceability and regulatory reporting.

- Reduced human error: Eliminates manual barcode scanning and data entry.

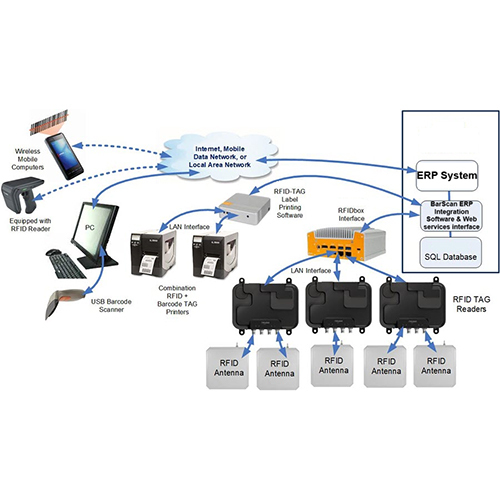

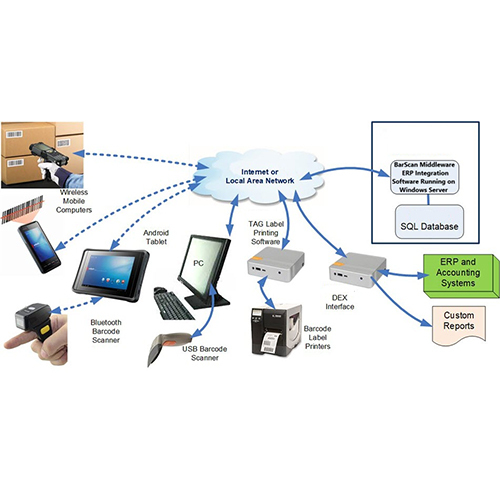

Integration Architecture

|

Component |

Role in Integration |

|

RFID Tags |

Store unique IDs for assets, inventory, or WIP items |

|

RFID Readers |

Capture tag data at checkpoints (fixed or handheld) |

|

Middleware/API |

Translates RFID reads into ERP-compatible formats (XML, JSON, CSV) |

|

ERP System |

Receives and processes RFID data into modules like inventory, production, dispatch |

ERP Compatibility & Tools

- SAP S/4HANA: Use SAP Auto-ID Infrastructure or integrate via REST APIs

- Microsoft Dynamics 365: Leverage Power Platform or third-party connectors

- Oracle NetSuite: Use RF-SMART or custom middleware

- Custom ERP: Build RESTful endpoints or use MQTT/HTTP bridges

Implementation Steps

- Define RFID events: What should happen when a tag is read? (e.g. update stock, trigger dispatch)

- Select hardware: Choose passive/active tags and fixed/mobile readers based on use case

- Design data flow: Map tag IDs to ERP fields (SKU, batch, location, timestamp)

- Deploy middleware: Use tools like ThingMagic Connect, TSL SDK, or custom scripts

- Test & validate: Simulate real-world workflows to ensure data accuracy and latency

- Train users: Ensure operators understand RFID checkpoints and ERP triggers

Seamless Integration for Any Enterprise

Whether you run a small business or manage a global supply chain, our RFID-ERP solution adapts to your needs. It scales easily and is compatible with major ERP platforms like SAP, Microsoft Dynamics, and Oracle, streamlining operations from inventory management to production monitoring. Middleware/API connectivity ensures straightforward integration, speeding up deployment while maintaining data consistency.

Deploy Your Way: On-Premise or Cloud

Choose the deployment type that suits your business operations. Both on-premise and cloud-based setups are available, providing flexibility in system management and data accessibility. Our implementation process typically takes 4-8 weeks, with dedicated experts guiding each phase for optimal performance and minimum disruption.

Robust Security and Compliance

Rest assured with comprehensive security features, including SSL encryption and role-based access control, ensuring data protection across all operations. The solution complies with ISO/IEC 18000 RFID and IT security standards, helping meet regulatory requirements in India. Periodic system health checks and 24/7 support assure ongoing reliability and compliance.

FAQ's of Integration of RFID with ERP:

Q: How does RFID integration with ERP benefit my inventory and asset management processes?

A: RFID integration automates identification and tracking of items, enabling real-time data capture for inventory and assets. This enhances accuracy, reduces manual data entry, increases traceability, and boosts overall operational efficiency by providing up-to-date information directly within your ERP system.Q: What deployment options are available for integrating RFID with ERP systems?

A: You can choose between on-premise and cloud-based deployments, both suitable for seamless integration with your existing ERP platforms. Depending on your business requirements, our team will recommend and implement the most effective setup.Q: How long does the implementation process typically take, and what does it involve?

A: The typical integration timeframe ranges from 4 to 8 weeks. The process includes initial assessment, customization of data fields, reports, and alerts, followed by system configuration and middleware/API connectivity to ensure real-time and reliable synchronization with your ERP software.Q: What types of RFID tags and communication protocols does this solution support?

A: Our system supports LF, HF, and UHF RFID tags and communicates via TCP/IP, web services, and RS232/485 protocols, ensuring compatibility with a wide range of hardware and integration requirements.Q: Is the RFID-ERP integration scalable for different company sizes and industries?

A: Yes, the solution is designed to be scalable for small, medium, and large enterprises across industries such as distribution, manufacturing, export, and services, offering customizable features to suit specific operational needs.Q: How is data security managed in this integrated solution?

A: Data security is ensured through SSL encryption and role-based access controls, allowing only authorized personnel to access sensitive information. Regular system health checks and compliance with IT security standards maintain ongoing protection.Q: What kind of support and maintenance is provided post-deployment?

A: We offer 24/7 remote support along with periodic system health checks to ensure optimal performance and rapid resolution of any issues, helping you maintain smooth and secure RFID-ERP operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email