- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

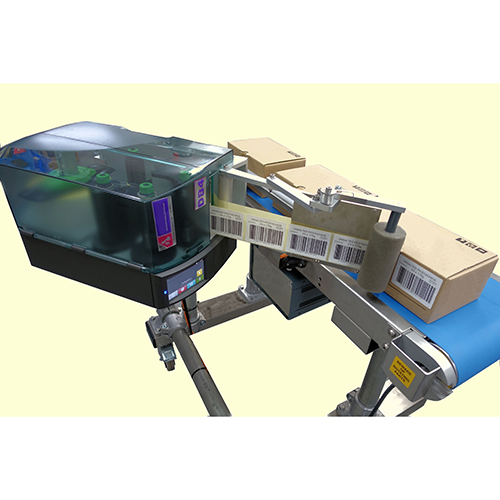

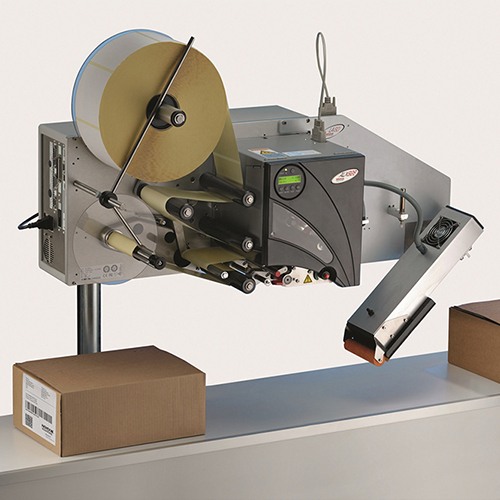

Industrial Print And Apply System

Product Details:

X

Product Description

Industrial Print and Apply Systems, below mentioned are details including their types, features, and use cases--are meant for high-speed, high-accuracy labeling in manufacturing and logistics environments.

What Is an Industrial Print & Apply System?

An automated solution that prints variable data (e.g., barcodes, batch codes, expiry dates) and immediately applies labels to products, cartons, or pallets. It integrates with ERP/WMS systems and supports real-time traceability.

Core Components

- Print Engine: Industrial-grade thermal transfer or direct thermal printer (Zebra, SATO, etc.)

- Applicator: Mechanism that applies the label--varies by surface and speed

- PLC Controller: Manages print/apply timing, communicates with upstream systems

Types of Applicators

|

Type |

How It Works |

Best For |

|

Tamp |

Pneumatic/electric arm presses label onto surface |

Flat boxes, cartons, static lines |

|

Tamp-Blow |

Vacuum pad holds label, burst of air applies it without contact |

Fragile items, contoured surfaces |

|

Wipe-On |

Label dispensed and wiped onto moving product via brush/roller |

High-speed lines, cylindrical cans |

|

Blow-On |

Air burst propels label from pad to product |

Irregular shapes, non-contact labeling |

|

Corner-Wrap |

Label applied to one panel and wrapped around adjacent side |

Shipping boxes, pallet corners |

Key Features

- Variable Data Printing: GS1, UDI, QR codes, batch codes

- Speed: Up to 50+ labels/min depending on label size and applicator type

- Resolution: Typically 300 dpi for barcode clarity

- Label Size Range: 20 mm to 150 mm wide; customizable

- Integration: Ethernet/IP, OPC-UA, Modbus, web-based UI

- Compliance: ISO/IEC 15416, ANSI grading, CFR Part 11 (pharma)

We can also help shortlist systems based on your target throughput, label material, and surface geometry. Contact us today.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email