- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

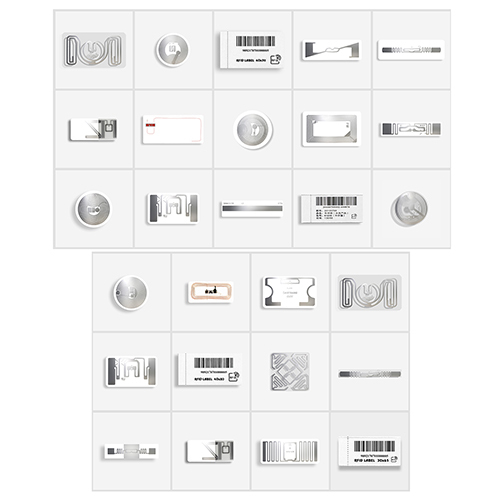

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

RFID Tags For Metal

Product Details:

- Product Type RFID Tags For Metal

- Material ABS/Metal Encapsulated

- Application Asset Tracking and Identification on Metal Surfaces

- Computerized No

- Automatic Grade Automatic

- Control System Contactless RFID System

- Drive Type Passive

- Click to View more

X

RFID Tags For Metal Product Specifications

- No

- Contactless RFID System

- Asset Tracking and Identification on Metal Surfaces

- Not Applicable (Passive Device)

- Grey/Blue (Customizable)

- Passive

- 85 x 25 x 3 mm (Typical)

- Anti-metal interference, Durable, Waterproof, High Temperature Resistant

- ABS/Metal Encapsulated

- 0.01 kg (Approx)

- Automatic

- Up to 512 bits (Memory depends on chip type)

- RFID Tags For Metal

- High (Depends on Reader, typically >95%)

- No Internal Power Source (Passive)

Product Description

RFID Tags for Metallic Surfaces

Specialized RFID tags are designed to overcome the signal interference caused by metal:

|

Tag Type |

Description |

Typical Use |

|

On-Metal Hard Tags |

Rigid, durable tags with foam or ferrite backing |

Industrial assets, tools, machinery |

Technologies Used

RFID tags for metal surfaces use advanced design techniques to ensure reliable performance:

- Anti-Interference Substrates: Foam, ferrite, or ceramic layers isolate the tag from metal reflection

- Tuned Antennas: Optimized to exploit or neutralize metals reflective properties

- Spacer Design: Creates a gap between the tag and metal to prevent detuning

- UHF Protocols (ISO 18000-6C): Most common for long-range, high-speed reads

Construction Details

- Materials:

- ABS or polycarbonate casing for ruggedness

- Ferrite or foam backing for signal isolation

- Adhesive or bolt-on mounting options

- Form Factors:

- Flat labels for laptops and servers

- Bolt-on tags for pipes and valves

- Embedded tags for tools and molds

Application Areas

RFID tags for metal surfaces are widely used in:

- Industrial Asset Tracking: Pipes, valves, machinery

- IT Asset Management: Servers, laptops, data center equipment

- Healthcare: Medical devices, sterilization trays

- Aerospace & Defense: Aircraft components, tools

- Construction: Steel beams, scaffolding

- Manufacturing: Automotive parts, production lines

Advantages

- Reliable Performance on Metal: Designed to overcome RF interference

- Durability: Resistant to heat, chemicals, and physical stress

- Flexible Form Factors: Suitable for flat, curved, and embedded surfaces

- Long Read Range: Optimized antenna design enables efficient scanning

- Improved Asset Visibility: Enables real-time tracking and inventory control

Would you like help selecting the best tag type for your specific metal asset or environment? Contact us today.

Optimized for Metal Surfaces

These RFID tags are engineered to effectively perform on metal surfaces, overcoming typical interference issues that hinder standard tags. Featuring anti-metal interference technology and durable encapsulation, they remain dependable in demanding industrial environments, whether for inventory management or machinery identification.

Flexible Mounting and Customization

Choose from adhesive, screw, or rivet mounting to best suit your application. The tags support customizations such as logo printing, barcode, serial number, and selectable surface finishes (matt/glossy). With color options including grey or blue, personalization helps with visual identification and branding.

Global Compatibility and High Performance

Operating on both UHF and HF frequencies, these tags are universally compatible with leading RFID readers worldwide. Their passive design requires no internal power, while delivering high accuracy and dependable data retention for over 10 years, ideal for long-term tracking and asset management.

FAQ's of RFID Tags For Metal:

Q: How can I mount the RFID tags for metal surfaces?

A: You can mount these tags using adhesive, screws, or rivets, depending on your installation requirements. This flexibility allows secure placement on various asset types in industrial or commercial settings.Q: What is the read range for these RFID tags and does it depend on the model?

A: UHF models offer read ranges up to 6 meters, while HF/NFC models reach up to 1 meter. The actual distance may depend on the selected chip type and RFID reader used.Q: When should I use RFID tags specifically designed for metal surfaces?

A: These tags are ideal when you need reliable performance tracking or identification directly on metallic assets, as they are built to counteract signal interference typically caused by metal.Q: Where can these RFID tags be used effectively?

A: They are suitable for asset management in factories, warehouses, construction sites, or any environment where items have metallic surfaces and require regular identification or inventory control.Q: What customizations are available for these RFID tags?

A: You can request logo printing, serial numbers, barcodes, and choose between matt or glossy surface finishes. Colors are customizable, usually available in grey or blue.Q: How durable are these RFID tags in harsh environments?

A: With IP68 waterproof and dustproof ratings and resistance to temperatures from -25C to +85C, these tags offer outstanding durability, making them suitable for indoor and outdoor industrial use.Q: What benefits do passive RFID tags offer for asset tracking?

A: Passive tags require no internal power source, ensuring low maintenance. They provide accurate, long-term tracking capabilities with high data retention and write endurance, greatly boosting asset management efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email