- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

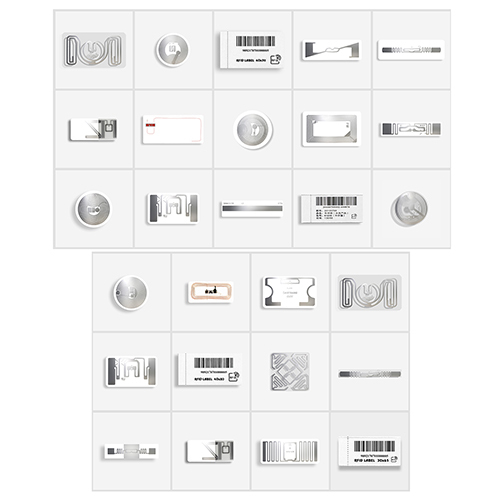

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

High Temperature RFID Tag

Product Details:

X

Product Description

Here is a detailed breakdown of High Temperature RFID Tags, covering their types, technologies, construction, application areas, and advantages:

Types of High Temperature RFID Tags

These tags are engineered to survive and operate in environments exceeding 150C, with some enduring up to 1000C degree Celsius:

|

Tag Type |

Temp Range |

Description |

|

PCB Tags |

150 to 180C |

Made from heat-resistant printed circuit boards; cost-effective for short-term use |

|

Ceramic Tags |

Up to 1000C |

Extremely heat-resistant; ideal for metallurgy and aerospace |

|

Glass Tube Tags |

180C |

Sealed in borosilicate or quartz glass; used in chemical and refining industries |

|

Plastic Tags |

100 to 200C |

Treated plastics for moderate heat resistance; lightweight and flexible |

|

Metal-Encased Tags |

Up to 300C+ |

Rugged casing for harsh industrial environments |

|

Flexible PI Tags |

150C |

Polyimide-based, bendable tags for shaped surfaces like robotic arms |

Technologies Used

High-temp RFID tags incorporate specialized technologies to ensure performance:

- Chip Packaging: Heat-resistant encapsulation to prevent failure

- RFID Protocols: Typically ISO/IEC 18000-6C (UHF), with some HF/LF variants

- Material Innovation:

- Zirconia/Alumina Ceramics: High dielectric constant for better RF performance on metal

- Epoxy Resin Substrates: Used in PCB tags for metal shielding

- Polyimide Coatings: Flexible and weather-resistant

Construction Details

- Encapsulation: Tags are sealed using high-temp adhesives, epoxy, or glass

- Form Factors:

- Embedded in molds or tools

- Surface-mounted with high-temp glue

- Encased in metal or ceramic shells

- Durability Enhancements:

- Shock and vibration resistance

- Corrosion-proof coatings

Application Areas

High-temp RFID tags are indispensable in:

- Metal Smelting & Foundries: Tracking ladles, molds, and furnace components

- Automotive Manufacturing: Paint lines, engine part tracking

- Aerospace & Defense: Monitoring components exposed to extreme heat

- Medical Sterilization: Surgical instrument tracking during autoclaving

- Chemical & Petrochemical: Asset tracking in corrosive, high-temp zones

- Electronics (SMT): Work-in-process tracking during soldering and reflow

Advantages

- Extreme Heat Resistance: Operate reliably in environments up to 1000C

- Non-Contact Identification: Efficient tracking without line-of-sight

- Durability: Withstand shock, corrosion, and vibration

- Traceability: Real-time monitoring and data collection

- Process Compliance: Ensures quality control in harsh conditions

- Flexible Deployment: Suitable for flat, curved, or embedded surfaces

If you are considering deploying these tags in a specific industry or process, we can help you choose the best type and technology for your needs. Want to dive into a particular use case? Contact us today.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email