- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

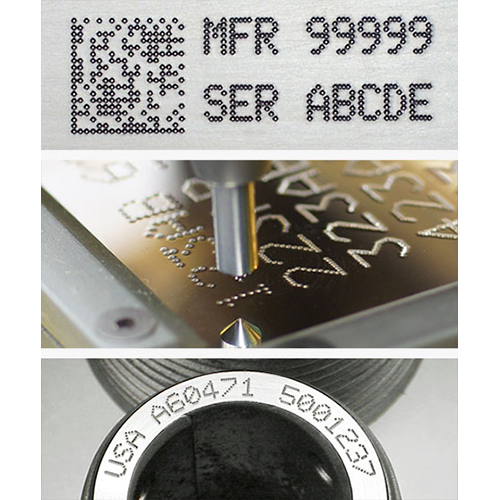

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

Ink Jet Printing

Product Details:

- Printing Speed 110 Meters/min

- Print Size Variable

- Usage Cartons, Packaging, Bottles

- Feature High Efficiency, Precise Printing, User-Friendly Operation

- Connectivity Options USB, Ethernet

- Printer Type Industrial Inkjet Printer

- Print Width Up to 12.7 mm

- Click to View more

X

Ink Jet Printing Product Specifications

- Electric

- Ink Jet Printing Machine

- Standard

- 110 Meters/min

- 1000 Impressions/hr

- Variable

- 24 Kilograms (kg)

- Stainless Steel

- 40 W

- Automatic

- Easy to Install, Durable

- Cartons, Packaging, Bottles

- Industrial Printing, Coding and Marking

- Box

- Up to 12.7 mm

- Industrial Inkjet Printer

- Blue and Silver

- USB, Ethernet

- High Efficiency, Precise Printing, User-Friendly Operation

Product Description

Here is a structured overview of Inkjet Printing covering its types, features, and applications, especially relevant for industrial, retail, and technical environments like yours.

Types of Inkjet Printing Technologies

|

Type |

Mechanism |

Typical Use Cases

|

|

Thermal Inkjet (TIJ) |

Heats ink to form bubbles that eject droplets |

Office printers, product coding, packaging |

|

Piezoelectric Inkjet |

Uses piezo crystals to push ink droplets |

High-resolution graphics, industrial marking |

|

Continuous Inkjet (CIJ) |

Constant ink stream with electrostatic deflection |

High-speed coding on moving products |

|

Drop-on-Demand (DOD) |

Ink released only when needed |

Labeling, barcodes, variable data printing |

For industrial marking in India (e.g. on cartons, bottles, PCBs), CIJ and TIJ are most common due to speed and cost-efficiency.

Key Features of Inkjet Printing

- High Resolution: Up to 1200 dpi for crisp text and graphics

- Non-contact Printing: Ideal for fragile or uneven surfaces

- Variable Data Capability: Serial numbers, barcodes, expiry dates

- Ink Versatility: Water-based, solvent-based, UV-curable, pigmented

- Substrate Flexibility: Paper, plastic, metal, glass, textiles

- Compact Footprint: Suitable for integration into production lines

- Low Maintenance: Especially with TIJ systems (cartridge-based)

Industrial & Commercial Uses

|

Sector |

Applications

|

|

Retail & Packaging |

Batch codes, expiry dates, barcodes on cartons and pouches |

|

Pharmaceutical |

UDI codes, blister pack marking, compliance labeling |

|

Electronics |

PCB traceability, component marking |

|

Textiles |

Fabric printing, design prototyping |

|

Advertising |

Large-format banners, posters, signage |

|

Office/Home |

Document printing, photo printing |

Would you like guidance regarding CIJ vs TIJ for your specific use case? Contact us today.

Intuitive Touchscreen Operation

Navigate printing tasks effortlessly with the large 7-inch touchscreen interface. Multiple language options make it accessible to a wide workforce, streamlining operation and reducing training time. The user-friendly control panel enables easy selection of font styles, sizes, and quick access to error and alarm notifications for smoother workflows.

Reliable Industrial Performance

Achieve precise and consistent results with high-speed printing, suitable for industrial applications such as coding, marking, and label printing. The machine handles up to 1,000 impressions per hour and adapts to variable print sizes and widths, ensuring flexibility across different packaging and production lines.

Designed for Durability and Mobility

Built with stainless steel and robust materials, this printer ensures longevity even in demanding environments. Casters offer effortless mobility, allowing the device to be repositioned as needed. The low-maintenance design and optional installation service make it a practical choice for dynamic industrial usage.

FAQ's of Ink Jet Printing:

Q: How is the ink jet printing machine installed and set up?

A: The machine is easy to install and comes with an optional professional installation service upon request. After physical placement, simply connect the unit to a 220V AC power source, set up the touchscreen interface, and import necessary printing data via USB or Ethernet.Q: What types of ink are supported for printing?

A: This printer supports both solvent-based and water-based inks, allowing users to choose the best option depending on their material type or environmental requirements.Q: When should maintenance be performed and what does it entail?

A: Thanks to its low maintenance design, regular checks are usually limited to inspecting the single nozzle for clogs and ensuring ink levels are sufficient. Error and low ink alarms notify users when attention is needed, helping prevent downtime.Q: Where can this printer be used within an industrial facility?

A: Mounted on casters for easy movement, the machine can be repositioned throughout the facility as needed, making it suitable for various production lines including cartons, bottles, and packaging areas.Q: What process is involved in importing external printing data?

A: External data import is facilitated through USB and Ethernet connectivity options. Users simply connect their device, transfer the printing files, and select the desired font and size using the touchscreen interface.Q: How does the alarm function benefit users during operation?

A: The built-in alarm system alerts operators to errors or low ink levels in real-time. This proactive notification system helps prevent printing inconsistencies and keeps production running smoothly.Q: What are the primary benefits of using this ink jet printer?

A: Key advantages include precise, high-speed printing, flexible data import, multi-language interface, effortless mobility, and low maintenance requirements. Its automatic operation ensures maximum efficiency for industrial-scale coding and marking.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email