- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

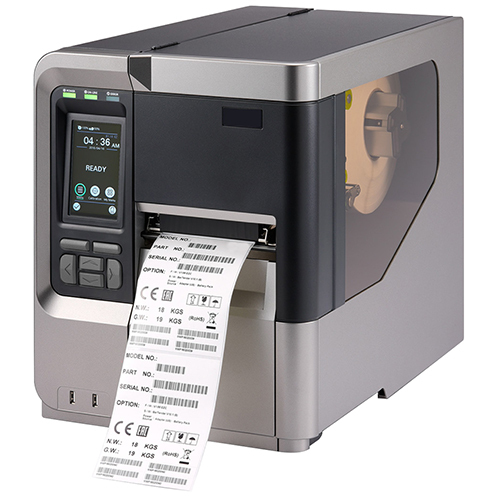

Barcode Printers

Product Details:

- Printer Type Thermal Transfer & Direct Thermal

- Connectivity Options USB, Serial Port

- Print Width 4.25 inches (108 mm)

- Printing Speed Up to 102 mm/sec

- Print Size Maximum 108 mm width

- Usage Ideal for inventory management, retail POS, asset tracking

- Feature High quality barcode printing, durable output, supports wide range of labels and tags, user friendly controls, consistent performance

- Click to View more

X

Barcode Printers Product Specifications

- Up to 1000 labels/day

- USB, Serial Port

- AC electric

- Thermal Transfer & Direct Thermal

- Rectangular

- ABS Plastic body

- 4.25 inches (108 mm)

- Barcode label printing for Retail, Warehousing, Pharmaceuticals, Manufacturing, Logistics

- Semi-automatic

- Grey & Black

- Desktop Barcode Printer

- Low

- Approximately 2.5 kg

- Fast labeling, Sharp printing, Reliable prints

- Up to 102 mm/sec

- Maximum 108 mm width

- Ideal for inventory management, retail POS, asset tracking

- Standard desktop size

- High quality barcode printing, durable output, supports wide range of labels and tags, user friendly controls, consistent performance

Product Description

Barcode printer technology is fundamentally based on two primary printing techniques: direct thermal printing and thermal transfer printing.

Direct Thermal Printing: This technique employs heat to initiate a chemical reaction on specially formulated thermal paper, resulting in a blackened area that forms the barcode. It is a cost-effective solution that does not necessitate the use of ink or ribbons; however, the labels may deteriorate when subjected to heat, light, or chemicals.

Thermal Transfer Printing: This approach utilizes heat to transfer ink from a ribbon onto the label substrate. It yields more resilient labels that can withstand various environmental conditions, making it appropriate for a broader spectrum of applications.

While other types of barcode printers exist, including dot matrix, inkjet, and laser printers, thermal printers remain the most prevalent choice due to their reliability and efficiency.

The DPI (dots per inch) of a barcode printer plays a crucial role in determining the resolution and overall quality of the printed barcode. Below are some typical DPI settings found in barcode printers:

203 DPI: This setting is adequate for basic barcode printing requirements. While it is cost-effective, it may not yield the sharpest images.

300 DPI: This is the standard resolution for a majority of barcode applications, striking a favorable balance between quality and cost.

406 DPI: This higher resolution offers clearer and more detailed barcodes.

600 DPI: This is the highest resolution available, making it suitable for applications that demand precise and high-quality barcodes, such as those used in electronics or for small labels.

Opting for higher DPI settings results in sharper and more detailed barcodes, which facilitate accurate scanning. However, these settings may also incur higher costs. The selection of DPI should be based on your specific requirements and the dimensions of the labels you intend to print.

For more details, contact us today.

Sharp, Reliable Printing Every Time

Featuring advanced thermal transfer and direct thermal technologies, this printer guarantees crisp, durable barcodes for a variety of tasks. The 203 dpi resolution ensures detailed outputs, while the wide media compatibility and rapid print speeds streamline operations. Whether for POS systems or warehouse inventory, expect consistently high-quality results.

User-Centric Controls and Sturdy Build

Designed with usability in mind, the printer's LED indicators and tactile buttons make operation straightforward for any user. Housed in a robust ABS plastic body, it is lightweight yet sturdy, adapting seamlessly to busy environments like retail desks and warehouse stations.

Versatile for Any Application

With its broad connectivity options, wide label capacity, and adaptability to various media types, this barcode printer fits diverse applications-from asset tracking to labeling shipments and products. Its standard desktop size and semi-automatic operation make it perfect for dynamic workplace requirements.

FAQ's of Barcode Printers:

Q: How do I change the label media in this barcode printer?

A: To change the label media, simply open the printer cover, remove the current roll, and load the new label roll or fan-fold stack onto the designated holder. Ensure the media guides are properly aligned, close the cover, and use the control panel to feed and calibrate the printer for optimal performance.Q: What types of labels are supported by this printer?

A: The printer accommodates continuous, die-cut, notch, and black mark labels with thicknesses from 0.08 mm to 0.18 mm. This versatility enables it to handle a wide range of labeling jobs for retail, warehousing, pharmaceuticals, and logistics applications.Q: When is it recommended to use thermal transfer versus direct thermal printing?

A: Thermal transfer is ideal when you need durable, long-lasting labels that withstand handling, heat, or chemicals, such as inventory or asset tags. Direct thermal printing is suitable for short-term use, like retail or shipping labels, as it avoids ribbon changes and simplifies the process.Q: Where can I use this barcode printer for maximum benefit?

A: This printer excels in environments requiring reliable barcode printing-inventory management, retail POS, pharmaceutical packaging, manufacturing lines, and logistics centers. Its durability and fast output suit places demanding consistent, high-volume label production.Q: What is the process for setting up the printer with computers or networks?

A: Connect the printer to a computer via USB or Serial Port, install the compatible drivers, and select the appropriate emulation mode (ZPL or EPL) as needed. Adjust printer settings using the control panel for optimal results, and you're ready to start printing.Q: How does this printer benefit overall business operations?

A: With its fast labeling capacity (up to 1000 labels daily), sharp and reliable prints, and adaptability to various media types, the printer streamlines labeling workflows, minimizes downtime, and enhances productivity across key business processes.Q: What maintenance is required to keep the printer running efficiently?

A: Routine maintenance involves periodically cleaning the print head with recommended solutions, ensuring the media and ribbon are free from dust, and checking for firmware updates. Regular upkeep ensures continual high-quality output and prolongs the printer's lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email