- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

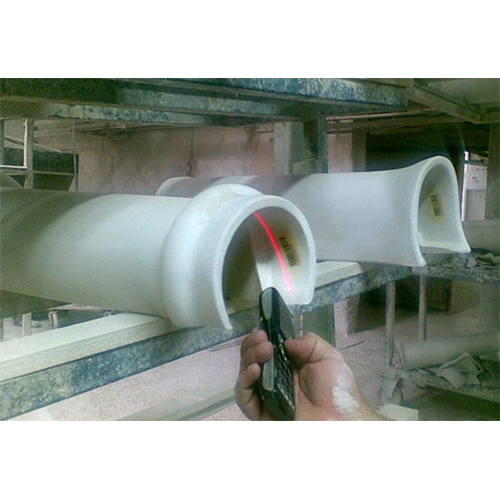

Kiln Fire proof Barcode Label

Product Details:

X

Product Description

For environments like kilns, furnaces, or high-temperature curing chambers, kiln fireproof barcode labels are a specialized solution designed to survive extreme heat, abrasion, and chemical exposure without losing readability. These labels are essential for industries like ceramics, metallurgy, and refractory manufacturing.

What Makes Kiln Fireproof Labels Unique?

- Material Composition: Typically made from specialized substrates that resist temperatures exceeding 1000C degree Celsius.

- Adhesive Type: High-temp adhesives or mechanical fastening (e.g., wire ties or rivets) since standard adhesives degrade under kiln conditions

- Print Method: Laser-etched or high-temp ink printed to prevent smudging or fading

- Barcode Integrity: Designed to maintain scannability even after exposure to fire, ash, or thermal shock

Common Applications

- Ceramic ware tracking during multi-stage firing

- Refractory brick identification in steel and glass furnaces

- Batch traceability in sintering and powder metallurgy

- Asset tagging for kiln furniture and fixtures

Benefits

- Zero label failure in high-heat zones

- Improved traceability across production cycles

- Reduced mislabeling and manual errors

- Compliance with ISO and industry-specific standards

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email