- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

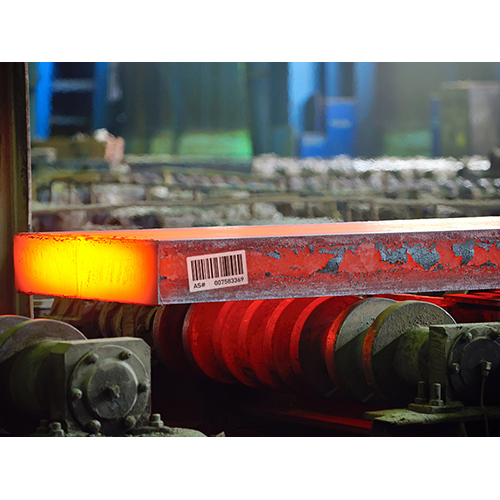

High Temperature Barcode Label

Product Details:

X

Product Description

High-temperature barcode labels are engineered to withstand extreme heat while maintaining legibility and adhesion. They are essential in industries where conventional labels would degrade or fail. Here is a comprehensive breakdown:

Types of High-Temperature Barcode Labels

|

Type |

Temperature Range |

Material |

Application Method |

|

Polyester Labels |

Up to 300F (150C) |

Polyester |

Manual or automated |

|

Polyimide (Kapton) Labels |

Up to 752F (400C) |

Polyimide film |

Common in electronics |

|

Ceramic Labels |

Up to 1500F (815C) |

Ceramic-based substrates |

Applied post-manufacturing |

|

Metal Foil Labels |

Up to 1250C |

Aluminum or stainless steel |

Mechanically attached |

Key Applications

- Automotive: Engine components, brake systems, and under-hood labeling

- Aerospace: Jet engine parts, fuselage components

- Electronics: PCB manufacturing, soldering processes

- Metallurgy: Steel and aluminum casting, billets, coils, ingots

- Laboratories: Autoclaves, sterilization tracking

- Tire Manufacturing: Vulcanization process labeling

Features & Benefits

- Extreme Heat Resistance: Withstands temperatures from 150 to 1250 degree Celsius

- Chemical & UV Resilience: Resistant to oils, acids, and sunlight exposure

- Durability: Maintains adhesion and legibility in harsh environments

- Printability: Compatible with thermal transfer and laser printing

- Versatile Application: Can be applied manually, semi-automatically, or automatically, even directly onto hot surfaces

Please contact us, if you would you like help choosing the right label type for a specific industry or use case?

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email