- Home Page

- Company Profile

-

Our Products

- BarCode And RFID Hardware

- Labels and Printing Ribbons

- Industrial High-Performance Labels And Tags

- Heat Resistant Labels And Tags

- Tear Resistant And Rip-Proof Tags

- Polyimide PCB Labels

- Wire And Cable Labels

- Tyre Barcode Label

- Sanitaryware Barcode Label

- Security Seal Labels

- Paint Protective Barcode Label

- Gas Cylinder Label Tag

- Barcode Tag And Label for Heat Treatment Process

- Metal Barcode Label And Tag

- RFID Tags And Labels

- System Integration Solutions

- Software Solutions

- Contact Us

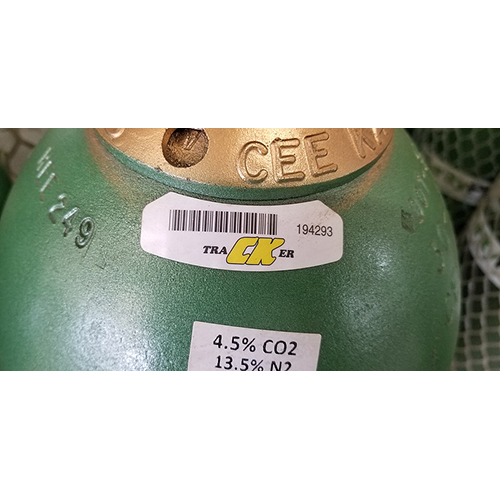

Gas Cylinder Barcode Lable

Product Details:

X

Product Description

GAS CYLINDER TAGS / LABELS ARE TYPICALLY:

- TAGS Made from metal-ceramic or stainless steel and LABELS made from Polyester (PET) / Polyimide for extreme durability

- Resistant to temperatures up to 800 degree Celsius, abrasion, and corrosion

- Embedded with QR codes or barcodes for scanning via mobile or PDA

- Permanently affixed to cylinders for lifetime traceability

Using barcode tags for gas cylinders is not just smart it is transformative for safety, efficiency, and compliance. Here is why they are becoming essential across industries:

Benefits of Barcode Tags for Gas Cylinders

1. Real-Time Tracking

- Instantly scan and identify each cylinder location, status, and history.

- Reduces loss and theft by maintaining visibility across the supply chain.

2. Enhanced Safety

- Tags can include critical data like gas type, pressure rating, and expiry date.

- Helps prevent misuse or mixing of incompatible gases.

3. Regulatory Compliance

- Meets industry standards for traceability (ISO, OSHA, PESO in India).

- Simplifies audits with digital logs and inspection records.

4. Inventory Management

- Automates stock counts and refill cycles.

- Flags cylinders due for maintenance or hydrostatic testing.

5. Operational Efficiency

- Speeds up check-in/check-out at depots or customer sites.

- Reduces manual errors and paperwork.

6. Lifecycle Monitoring

- Tracks each cylinder from manufacture to retirement.

- Enables predictive maintenance and replacement planning.

7. Integration with ERP Systems

- Syncs with software like SAP, Oracle, or custom apps.

- Supports analytics for usage trends and cost optimization.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email