स्टील कॉइल बारकोड लेबल

उत्पाद विवरण:

- प्रॉडक्ट टाइप

- मटेरियल Polyester or Synthetic Paper

- एप्लीकेशन Steel Coil Identification, Inventory Tracking, Logistics

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- अधिक देखने के लिए क्लिक करें

स्टील कॉइल बारकोड लेबल उत्पाद की विशेषताएं

- Polyester or Synthetic Paper

- Custom size as per requirement (e.g., 100 mm x 150 mm)

- High Precision; error < 1%

- 220V AC (Printer)

- Up to 10,000 labels/day (printing capability)

- Steel Coil Identification, Inventory Tracking, Logistics

- 0.5 - 1.5 kg per 1000 labels

उत्पाद वर्णन

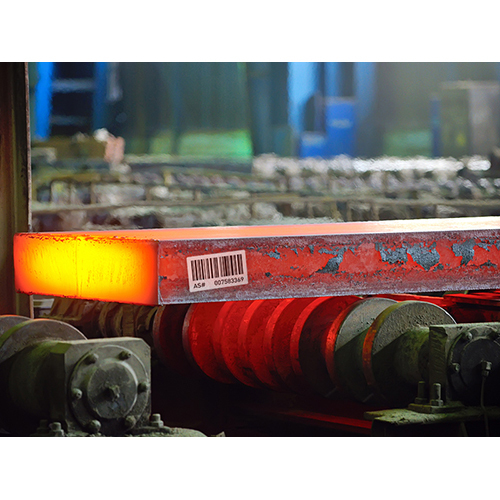

Choosing the right label material for steel coils, especially hot rolled and cold rolled requires balancing durability, adhesion, and environmental resistance. Here's a breakdown of the best materials based on coil type and application:

Best Label Materials for Steel Coils

Hot Rolled Steel Coils

Hot rolled coils have rough, sometimes oily surfaces and may be exposed to high temperatures and outdoor conditions.

Recommended Materials:

- Polyimide (e.g., Kapton)

- Heat-resistant up to 300C degree celsius

- Excellent chemical and abrasion resistance

- Ideal for coils stored or processed in high-temperature environments

- Polyester (PET) with High-Tack Adhesive

- Strong adhesion to rough surfaces

- Weather-resistant and UV-stable

- Cost-effective for general industrial use

- Aluminum Foil Labels

- Metal-compatible and heat-tolerant

- Can be riveted or welded for permanent ID

- Useful for long-term outdoor storage

Cold Rolled Steel Coils

Cold rolled coils have smoother surfaces and are typically used in cleaner, controlled environments.

Recommended Materials:

- Polyester (PET)

- Smooth adhesion and print clarity

- Compatible with thermal transfer printing

- Ideal for indoor use and automated scanning

- Vinyl Labels

- Flexible and conformable to curved surfaces

- Moisture-resistant

- Good for short-term applications

- Paper Labels (with protective coating)

- Economical for temporary tracking

- Requires clean, dry surface

- Not suitable for harsh environments

Adhesive Considerations

|

Adhesive Type |

Best For |

Notes |

|

High-Tack Acrylic |

Hot rolled coils |

Strong bond on rough/oily surfaces |

|

Rubber-Based Adhesive |

Cold rolled coils |

Quick stick, indoor use |

|

Heat-Activated Glue |

High-temp environments |

Requires curing or heat exposure |

|

Magnetic Backing |

Temporary labeling on metal |

Easy to remove, no residue |

Outstanding Durability and Reliability

Engineered for heavy-duty usage, these barcode labels withstand harsh industrial conditions including exposure to chemicals, moisture, and extreme temperatures. The high-strength adhesive ensures a long-lasting bond, even on oily or rough metal surfaces, minimizing risks of detachment during handling or transport.

Versatile Printing and Barcode Compatibility

Designed for use with both thermal transfer and direct thermal printers, these labels support a variety of 1D and 2D barcodes-ideal for steel coil identification and tracking. High precision encoding and printing assures fast, error-free scanning throughout logistical processes, improving operational efficiency.

Customized Solutions for Steel Industry Applications

Available in custom sizes and finishes (matte or glossy), these labels easily fit your operational needs. Optional lamination further enhances resistance, while the barcode management software streamlines batch printing and label control, accommodating up to 10,000 labels daily for scalable production demands.

FAQ's of Steel Coil Barcode Label:

Q: How do I apply the steel coil barcode labels to oily or metal surfaces?

A: Simply clean the application area to remove loose debris; the high-strength permanent adhesive is engineered to stick securely even on oily or metallic surfaces, making it suitable for steel coils and other industrial metals.Q: What is the recommended printer model for these labels?

A: These barcode labels work flawlessly with industry-leading thermal transfer and direct thermal printers such as Zebra, Sato, TSC, and Citizen. Ensure your printer supports the correct label size and print technology for optimal results.Q: When should I choose lamination for my barcode labels?

A: Lamination is optional and recommended in environments with frequent abrasion or heavy exposure to chemicals. It provides an added protective layer for maximum label longevity and clarity.Q: Where are these barcode labels commonly used?

A: They are primarily used in steel coil identification, inventory tracking, and logistics within manufacturing plants, warehouses, and distribution centers, ensuring reliable data capture and traceability.Q: What process should I follow for high-volume label printing?

A: Utilize the barcode management software to design, batch print, and manage labels. Connect to compatible printers set at 220V AC, and take advantage of the system's ability to produce up to 10,000 labels per day for large-scale operations.Q: What are the key benefits of using these labels for steel coil management?

A: These labels provide excellent adhesion on challenging surfaces, resist chemicals and weather, allow quick barcode scanning, and support customization. This leads to streamlined inventory management, reduced errors, and improved operational efficiency.Q: How long can I store the unused labels, and how should I store them?

A: The labels have a storage life of up to 2 years. Store them in a cool, dry environment away from direct sunlight to maintain adhesive strength and printing quality.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+